Vibrating screen is a common screening equipment that separates granular materials according to different particle sizes through the action of vibration force and screen mesh.

What are the types of vibrating screens? Vibrating screens can be divided into many types according to different screening requirements and working principles. These different types of vibrating screens play important roles in different application scenarios.

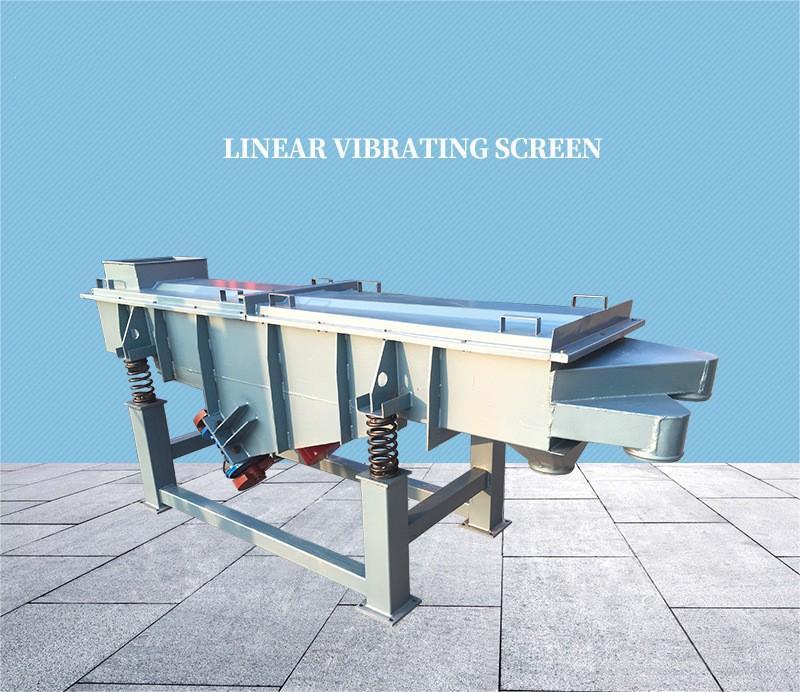

Vibrating linear screen: Vibrating linear screen is a kind of linear vibrating screening equipment. It uses vibration force to make materials move linearly on the screen to achieve screening and classification of materials. Vibrating linear screens are suitable for large-volume, continuous operations and have the characteristics of efficient screening, large processing capacity and good stability.

Vibrating circular screen: Vibrating circular screen is a circular vibrating screening equipment. It uses vibration force to make the material rotate on the circular screen to achieve screening and grading of the material. The vibrating circular screen is suitable for wet screening or screening of sticky materials, with high efficiency screening, uniform distribution and high processing capacity.

Vibrating air flow screen: Vibrating air flow screen is a screening equipment that uses a combination of air flow and vibration force. It suspends the granular materials in the air flow through the action of air flow, and sieves the materials on the screen through the action of vibration force. It is suitable for screening fine powder and ultra-fine powder materials, and can effectively remove fine particles and impurities and improve product quality.

Vibrating centrifugal screen: Vibrating centrifugal screen is a centrifugal vibrating screening equipment. It uses centrifugal force to make materials move centrifugally on the screen to achieve screening and classification of materials. The vibrating centrifugal screen is suitable for screening fine-grained materials and has the characteristics of efficient screening, high precision and large processing capacity.

These are common types of vibrating screens, and each type has its own specific working principles and applicable occasions. When selecting a vibrating screen, the most suitable type needs to be determined based on the characteristics of the material, screening requirements and production needs. In addition, the vibrating screen can also be customized according to the number of screen layers, the shape and size of the screen holes and other factors to meet different screening needs. By selecting the appropriate vibrating screen type and high-quality equipment, screening efficiency can be improved, product quality can be improved, and production efficiency can be improved.