Dry vibrating screens for mining and industrial is a screening equipment commonly used in mining and industrial fields for dry screening of granular materials. It uses vibration force and the screening effect of the screen to separate and classify materials according to different particle sizes. The following is a detailed introduction to dry vibratory screen separators for mining and industrial.

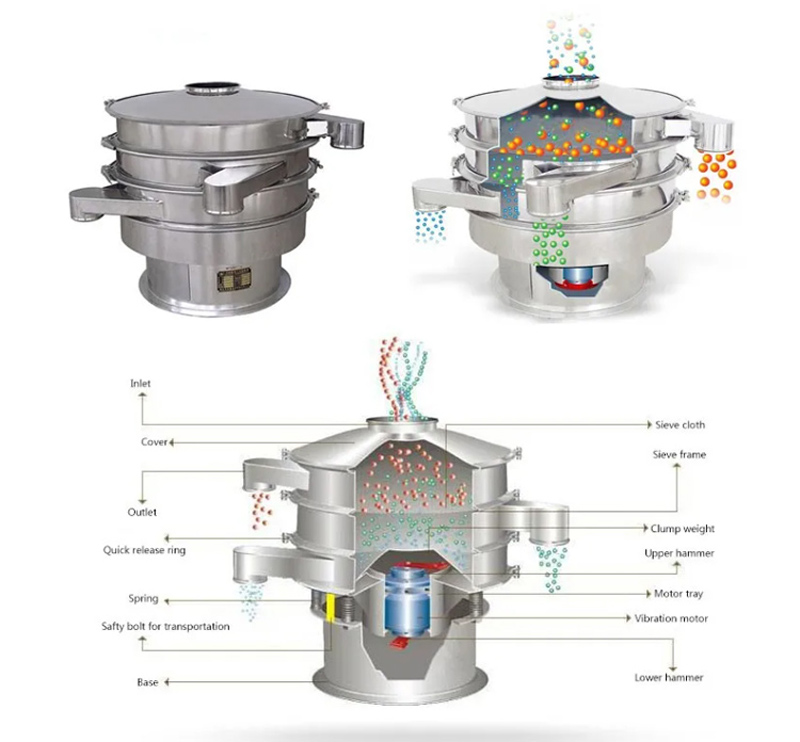

Dry vibrating screens for mining and industrial are mainly composed of screen boxes, vibrators, screens, etc. The vibrator generates vibration force through the excitation source and transmits it to the screen box and screen mesh, so that the materials are screened on the screen mesh. The material passes through the pore size of the screen and is divided into different levels according to the particle size. The larger particles are separated, while the smaller particles pass through the screen.

Dry vibrating screens for mining and industrial have the following features and advantages:

High screening efficiency: The vibration force and the screening effect of the screen make the materials quickly separate, realize an efficient screening process, and improve the screening efficiency.

Large processing capacity: Dry vibrating screens for mining and industrial have large screen area and processing capacity, can handle large quantities of materials, and are suitable for high-volume production environments.

Precise classification: The aperture size of the screen can be selected according to needs, which can achieve precise classification and classification to meet the requirements of different granular materials.

Flexible application: Dry vibrating screens for mining and industrial are suitable for screening a variety of granular materials, including ores, coal, metal powders, chemical raw materials, etc., and are widely used in mining, metallurgy, chemicals, building materials and other industrial fields.

Dry vibrating screens for mining and industrial have a wide range of applications in mining and industry, including the following aspects:

Mining and metallurgical industry: used for screening and grading of ores, dividing raw materials into ores of different particle sizes to meet subsequent mineral processing and smelting process requirements.

Coal industry: used for screening and grading coal, dividing coal into coal products of different particle sizes, and used for coal washing and coal processing.

Chemical industry: used for screening and classifying chemical raw materials, such as fertilizers, plastic granules, etc., to control the particle size and quality of products.

Building materials industry: used for screening granular materials such as limestone, quartz sand, sand and gravel, and used to produce building materials such as concrete and mortar.

In short, dry vibrating screens for mining and industrial is an important screening equipment that is widely used in mining and industrial fields. It has the advantages of high efficiency, large processing capacity, and precise classification, providing a reliable solution for screening and classifying granular materials in the production process.