If you choose a wholesale vibrating screen separator for granule, then you need to consider some important factors. Screen shaker separator, as a common screening equipment, is widely used in many industries, such as chemical industry, food, medicine, metallurgy and mining, etc.

First, you need to focus on the quality and performance of your device. A high-quality vibrating screen separator should have stable vibration performance, efficient screening capacity and durable structure. Ensure that the vibrating screen separator uses advanced manufacturing processes and high-quality materials to ensure the reliability and long-term use of the equipment.

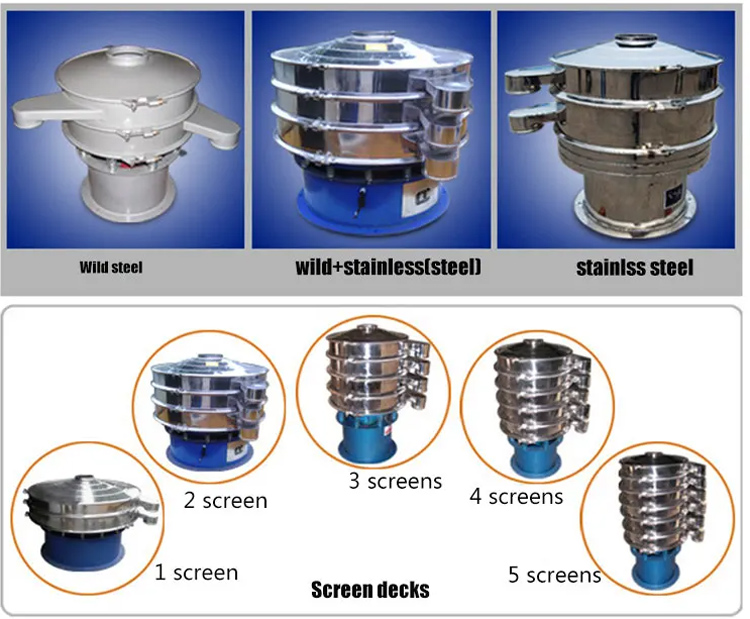

Secondly, you need to choose the appropriate model and specifications according to your actual needs. Vibrating screen separators are available in different models such as single-layer, double-layer and multi-layer. Each model is suitable for different screening needs of granular materials. According to your product characteristics and screening requirements, select the appropriate vibrating screen separator model to ensure that the equipment can meet your production needs.

Third, consider the supplier's reputation and after-sales service. Choosing a reliable supplier is the key to ensuring the quality and after-sales service of the vibrating screen separator. Understand the reputation and reputation of your suppliers, and read customer reviews and feedback to ensure that the partnership you establish with your suppliers is well supported and serviced.

Additionally, you should also consider the price factor. The prices of different models and brands of vibrating screen separators may vary. When choosing a wholesale vibrating screen separator, you need to comprehensively consider the quality, performance and price of the equipment and compare with multiple suppliers to get the most cost-effective product.

Finally, make sure your supplier can provide comprehensive technical support and after-sales service. The vibrating screen separator may encounter some problems or require maintenance during use, so the supplier should be able to provide timely technical support and training and solve the problems you encounter.

First of all, the vibrating screen separator can separate granular materials according to different particle sizes, thereby meeting the screening and classification needs of granular materials in different industries. Whether it is chemical, food, pharmaceutical, metallurgy or mining industries, granular materials need to be screened to ensure product quality and production efficiency.

Secondly, the vibrating screen separator has a multi-layer screen structure, which can screen multiple particle sizes at the same time, improving screening efficiency and production capacity. The design of the multi-layer screen can be adjusted according to different screening requirements, making the screening process more flexible and adjustable.

Third, the vibrating screen separator adopts a sealed design, which can effectively prevent the leakage of granular materials and environmental pollution, and protect the safety of operators and the hygiene of the production environment. The sealed design can also reduce the generation of dust and improve the working environment.

In addition, vibrating screen separators have a wide range of applications. Granular materials from different industries, whether coarse or fine, can be screened and classified by vibrating screen separators. This wide range of applicability makes vibrating screen separators essential equipment in many industries.

Finally, choosing a wholesale granular vibrating screen separator can bring economic benefits. Efficient screening capacity and production capacity can improve production efficiency and reduce labor costs. At the same time, through screening and grading, product quality can be improved and market competitiveness increased, thereby bringing better economic returns.

In short, choosing a wholesale vibrating screen separator for granule is an important decision that requires comprehensive consideration of equipment quality, performance, price, and the supplier's reputation and after-sales service. Through careful evaluation and comparison, you can choose a vibrating screen separator that suits your needs, increase production efficiency, improve product quality, and achieve better economic benefits.