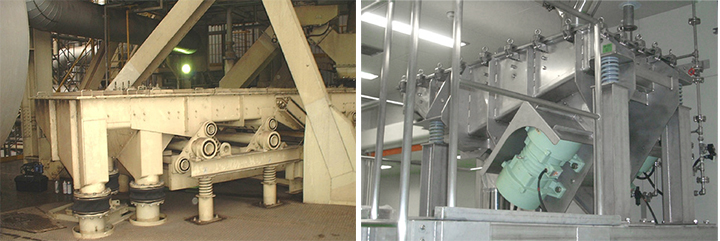

Stone powder vibrating screen is a device used for screening and grading granular materials. It usually adopts a multi-layer screen design. The aperture size of each layer of the screen is different, which can achieve multi-level grading and classification, and improve the screening efficiency. Ensure the uniformity and quality of the product; the powerful impurity removal ability can effectively remove impurities and foreign matter in the stone powder, and ensure the purity and quality of the product; the reliable and stable structure of the stone powder vibrating screen ensures the stable operation and long-term use of the equipment. The stone powder vibrating screen is an efficient and reliable screening equipment, which has important application and promotion value for stone powder production enterprises.

When the stone powder vibrating screen starts working, the vibration motor generates an excitation force through the vibrator, causing the entire screen body to vibrate. This vibration movement causes the stone powder to move relative to the screen, thereby realizing the screening and grading of particles. The stone powder forms three motion states on the vibrating screen: free fall motion: the particles move downward under the action of gravity on the vibrating screen; projectile motion: the particles move upward under the action of vibration force; falling motion: the particles move back and forth on the screen. These motion states are combined so that particles can quickly pass through the sieve holes or be blocked on the sieve during the screening process, thus achieving particle separation and classification. By adjusting the magnitude and frequency of the vibration force, the motion state of the particles on the sieve can be controlled, thereby achieving particle screening and grading of particles of different particle sizes. The stone powder vibrating screen uses the principle of vibration mechanics to achieve particle screening and grading through vibration motion. It has an efficient and accurate screening effect and is widely used in the screening of various granular materials.

The stone powder vibrating screen is a particle screening equipment widely used in industrial production, and its scope of application covers multiple industries and fields. First, in the mining field, the stone powder vibrating screen is often used for the screening and grading of minerals such as limestone, coal, and metal mines, helping to improve the utilization rate of ore and product quality. Secondly, in the building materials industry, the stone powder vibrating screen can be used for the screening and particle size adjustment of building materials such as cement, gypsum, and glass to ensure that the quality of building materials products meets the standards. In the chemical industry, the stone powder vibrating screen is suitable for particle screening and grading of chemical products such as fertilizers, plastics, and pigments, which helps to improve the production efficiency of chemical products. At the same time, the food industry also widely uses stone powder vibrating screens to screen and remove impurities from food raw materials such as flour, powdered sugar, and starch to ensure food safety and quality. In the pharmaceutical field, stone powder vibrating screens can be used for screening and particle size adjustment of medicinal raw materials such as medicinal materials, Chinese medicine granules, and powders to ensure the purity and stability of medicines. In addition, stone powder vibrating screens are often used in environmental protection projects to treat solid waste, sludge and other waste materials, which helps to achieve resource recovery and environmental protection goals. In the metallurgical industry, stone powder vibrating screens are suitable for particle screening and grading of metal materials such as steel, aluminum, and copper, improving the quality and utilization rate of metal products. In the agricultural field, stone powder vibrating screens are also widely used for screening and grading agricultural granular materials such as seeds, feed, and fertilizers to promote the development of agricultural production. In general, stone powder vibrating screens play an important role in many fields such as mining, building materials, chemicals, food, medicine, environmental protection, metallurgy, and agriculture. It is a powerful and widely applicable screening equipment.

Precise screening: Through the principle of vibration mechanics and multi-layer screen design, the stone powder vibrating screen can achieve precise particle screening to ensure the stability and consistency of the product. Adjusting particle size: The stone powder vibrating screen can adjust the aperture and vibration parameters of the screen as needed to achieve particle screening and grading of particles in different particle size ranges to meet the particle size requirements of the product.

Strong adaptability: The stone powder vibrating screen is suitable for materials of different particle sizes, shapes and properties. It has strong versatility and adaptability and can meet diverse screening needs.

The importance of stone powder vibrating screen in industrial production is self-evident. Its functions are multidimensional and diverse, including screening, grading, impurity removal, improving processing efficiency, controlling product quality, resource utilization and improving the production environment. Through the vibrating screen, raw materials can be classified according to particle size to ensure product quality and meet production requirements. The vibrating screen can effectively remove impurities and foreign matter and improve product purity and quality. Product quality can be guaranteed by accurately controlling the particle size and shape of granular materials. The vibrating screen also helps to recycle resources, reduce environmental pollution, and conform to the concept of sustainable development. Improve the production environment, reduce dust and noise pollution, and protect the health and safety of employees. Stone powder vibrating screen plays an indispensable role in industrial production and is of great significance for improving production efficiency, controlling product quality, protecting the environment and promoting sustainable development.