Stainless steel ultrasonic vibrating screen is an advanced screening equipment that combines the corrosion resistance of stainless steel and the efficient screening ability of ultrasonic technology. Made of high-quality stainless steel, the stainless steel ultrasonic vibrating screen has good corrosion resistance and wear resistance, can adapt to various working environments, and meets hygiene standards. It is suitable for processing materials with high material requirements such as food and medicine. The stainless steel material makes the stainless steel ultrasonic vibrating screen easy to clean and maintain. Stainless steel has good corrosion resistance and can resist the corrosion of chemical substances. At the same time, the surface is smooth, impurities are not easy to adhere, and it is more convenient to clean. Stainless steel ultrasonic vibrating screen is an indispensable and important equipment in various industries, providing enterprises with important production guarantees and competitive advantages.

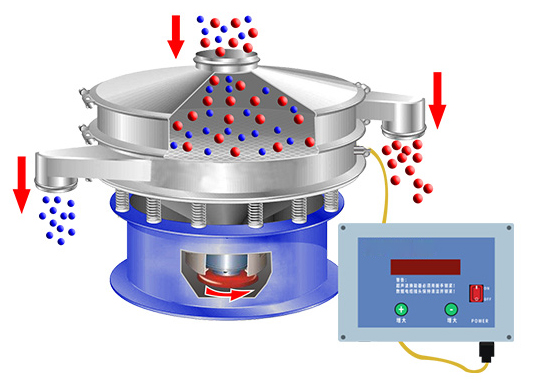

The stainless steel ultrasonic vibrating screen includes a vibrating screen box with a screen or screen plate inside. Driven by a motor, the vibrating screen box vibrates horizontally, vertically or tilted, so that the material moves on the screen to achieve screening. Traditional vibrating screens achieve screening by vibration, but the effect is limited when dealing with some difficult-to-screen materials. Stainless steel ultrasonic vibrating screens add an ultrasonic generator to the vibrating screen. The ultrasonic generator transmits ultrasonic signals to the screen through the ultrasonic vibration device, causing the screen to produce high-frequency micro-vibrations. This micro-vibration can effectively destroy the adhesion between materials, reduce particle blockage, and improve the screening effect. The effect of ultrasound makes the material more evenly distributed on the screen, and at the same time can penetrate the particle layer, so that fine particles that are difficult to screen can also be effectively separated. The high-frequency vibration of ultrasound can also help improve screening accuracy, reduce dust generation, and improve screening efficiency. The stainless steel ultrasonic vibrating screen achieves a more efficient screening process through the combination of vibration and ultrasound. The effect of ultrasound improves the shortcomings of traditional vibrating screens, improves screening accuracy and efficiency, reduces blockage, and reduces energy consumption and maintenance costs.

In the food processing industry, stainless steel ultrasonic vibrating screens are widely used in the screening of food raw materials such as flour, starch, powdered sugar, and seasonings. Ultrasonic technology can improve screening accuracy and ensure quality and hygiene standards in the food production process. In the pharmaceutical production process, stainless steel ultrasonic vibrating screens can be used for the screening of pharmaceutical raw materials and the grading of intermediates to ensure the purity and quality of pharmaceuticals, meeting the strict requirements of pharmaceutical production. In the chemical industry, stainless steel ultrasonic vibrating screens can be used for screening and grading chemical raw materials, such as plastic particles, pigments, coatings and other materials, to improve product quality and production efficiency. In the production of building materials, stainless steel ultrasonic vibrating screens can be used for the screening of building materials such as cement, lime, and coal powder to ensure that the particle size of the raw materials meets production requirements and improve product quality. In the mining industry, stainless steel ultrasonic vibrating screens can be used for the screening of mining raw materials such as coal, ore, and metal powder to improve the utilization rate and production efficiency of ore. In environmental protection fields such as wastewater treatment and solid waste treatment, stainless steel ultrasonic vibrating screens can be used for environmental protection processes such as solid-liquid separation and waste screening to improve processing efficiency and reduce environmental pollution. Stainless steel ultrasonic vibrating screens are suitable for food, medicine, chemicals, building materials, mining, environmental protection and other industries, and can meet the screening needs of different materials. Advantages of stainless steel ultrasonic vibrating screens

Energy saving and environmental protection: Ultrasonic vibrating screens can reduce dust generation and energy consumption during screening, meeting the requirements of energy saving and environmental protection. At the same time, no additional media is needed, which saves production costs.

Strong adaptability: Stainless steel ultrasonic vibrating screen is suitable for materials of different particle sizes, humidity and viscosity, has strong adaptability, and can cope with various screening needs.

Stainless steel ultrasonic vibrating screen can reduce energy consumption and raw material waste during the screening process, and no additional media is needed to save production costs. By reducing energy consumption and reducing waste generation, enterprises can effectively control costs and improve profitability. As an advanced screening equipment, it brings more convenient and reliable production solutions to enterprises, helping enterprises achieve sustainable development and long-term success. In the fierce market competition, having advanced production equipment can enable enterprises to stand out in the market and win more customers and market share. The introduction of advanced equipment such as stainless steel ultrasonic vibrating screen by enterprises can promote the technological innovation of enterprises, improve the level of production technology, continuously optimize the production process, and improve the competitiveness and sustainable development capabilities of enterprises.