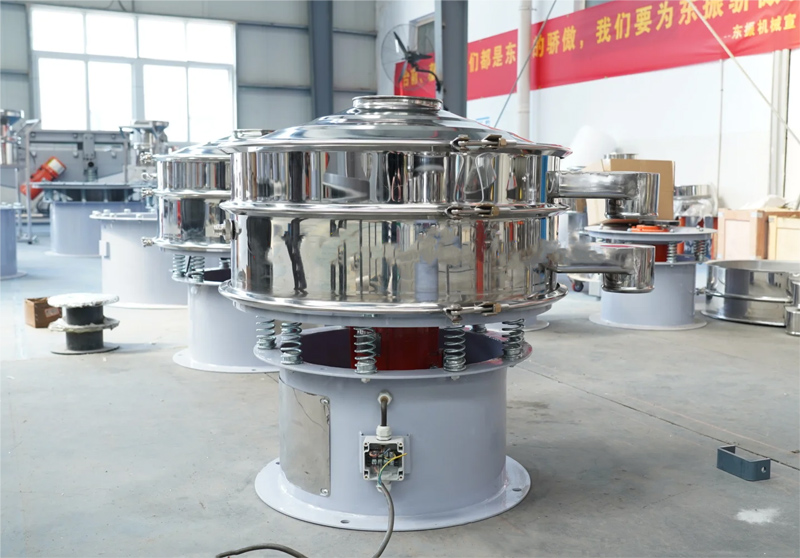

Multi-layer sealed vibratory screen separator is a piece of equipment commonly used for screening and classifying granular materials. It separates raw materials according to different particle sizes through the action of vibration force and screen mesh, thereby achieving screening and classification of granular materials.

The working principle of multi-layer sealed vibratory screen separator is based on the synergistic effect of vibration force and screen mesh. The equipment uses the vibration force generated by the motor to vibrate the entire screen machine, thereby promoting the rapid transfer of materials on the screen. At the same time, there are multiple layers of screens inside the screen machine, and each layer of screens has different aperture sizes. Under the action of vibration, the materials are separated through the sieve holes. The larger particles of materials are blocked on the upper screen, while the smaller particles of materials pass through the smaller sieve holes, and finally the materials are classified and screened.

Multi-layer sealed vibratory screen separator is widely used in many industries, mainly used for screening and classifying granular materials. Here are some common application scenarios:

Chemical industry: Multi-layer sealed vibratory screen separator can be used for screening and classifying granular materials in the chemical industry. For example, it is used for screening granular chemical raw materials, classifying granular materials, etc.

Food industry: In the food industry, multi-layer sealed vibratory screen separators are often used for screening and classifying granular materials during food processing. For example, it is used for screening granular materials such as flour, powdered sugar, and starch.

Pharmaceutical industry: Multi-layer sealed vibratory screen separator is widely used in the pharmaceutical industry. It can be used for screening and grading of medicinal powders, and screening of medicinal materials.

Metallurgical industry: The screening of granular materials in the metallurgical industry is also one of the application fields of multi-layer sealed vibratory screen separator. For example, it is used for screening ores, classifying metal powders, etc.

Mining industry: In the mining industry, multi-layer sealed vibratory screen separator can be used for screening and grading of ores, as well as screening of coal, limestone and other materials.

The application scenarios of Multi-layer sealed vibratory screen separator are not limited to the above industries, but can also be customized according to the needs of different industries. It has the characteristics of efficient screening, adjustability and sealing design, which can improve production efficiency, improve product quality and meet the screening needs of different materials.

Multi-layer screen structure: Multi-layer sealed vibratory screen separator is usually composed of multiple layers of screens, each layer of screen has different aperture sizes.

Sealing design: Multi-layer sealed vibratory screen separator adopts sealing design, which can effectively prevent material leakage and environmental pollution.

Efficient screening: Multi-layer sealed vibratory screen separator uses vibration force to drive the screen for screening, which has an efficient screening effect.

Adjustability: Multi-layer sealed vibratory screen separators usually have adjustable vibration force and screen angle, which can be adjusted according to the characteristics and screening requirements of different materials.

In short, the multi-layer sealed vibratory screen separator is an efficient equipment for screening and classifying granular materials. It achieves fine screening and separation of granular materials through the action of multi-layer screen structure, sealing design and vibration force. Multi-layer sealed vibratory screen separator is widely used in chemical, food, pharmaceutical, metallurgy, mining and other industries. It can improve production efficiency, improve product quality, and meet the screening needs of different materials.